Posted On 13 February, 2026 By Arvico Rubber Leave a Comment Export Quality...

Read MoreOur Blogs

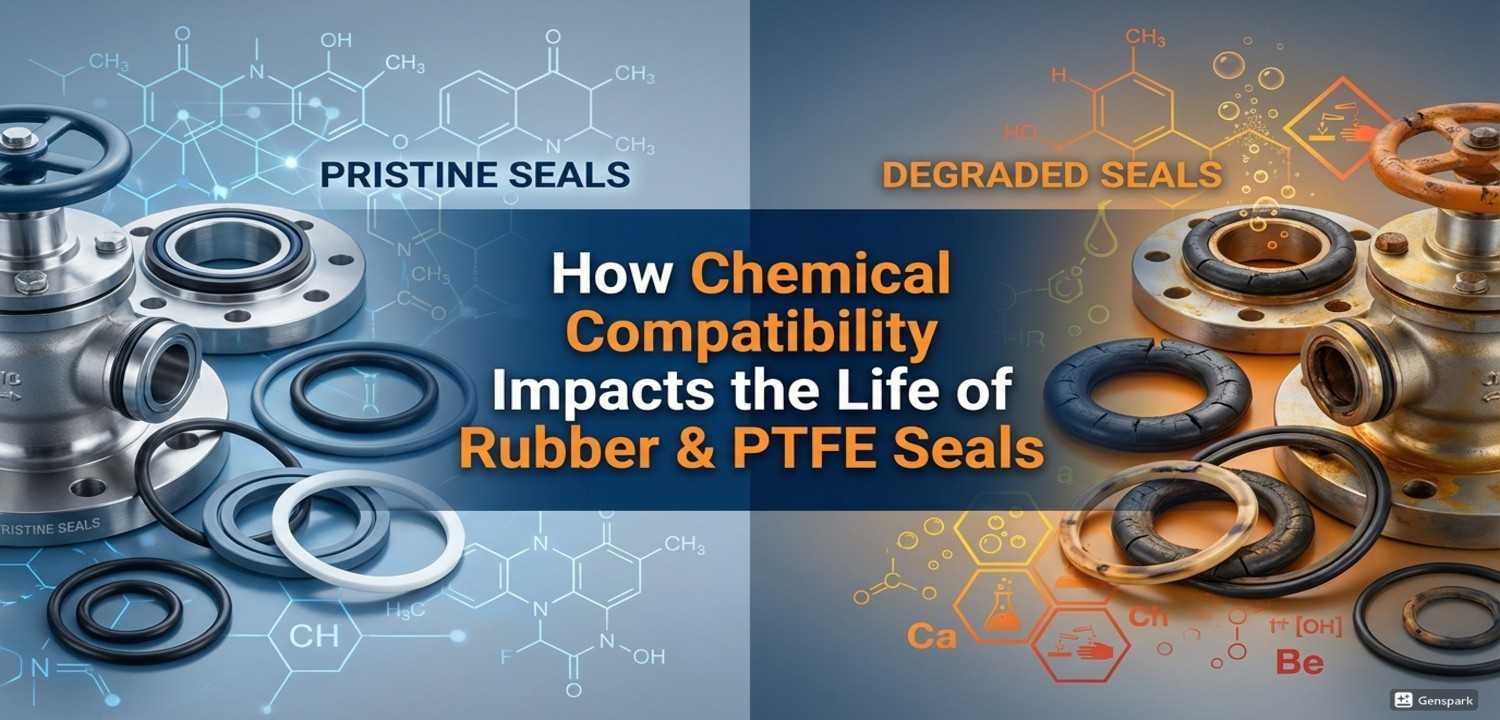

How Chemical Compatibility Impacts the Life of Rubber & PTFE Seals

Posted On 13 February, 2026 By Arvico Rubber Leave a Comment What Engineers...

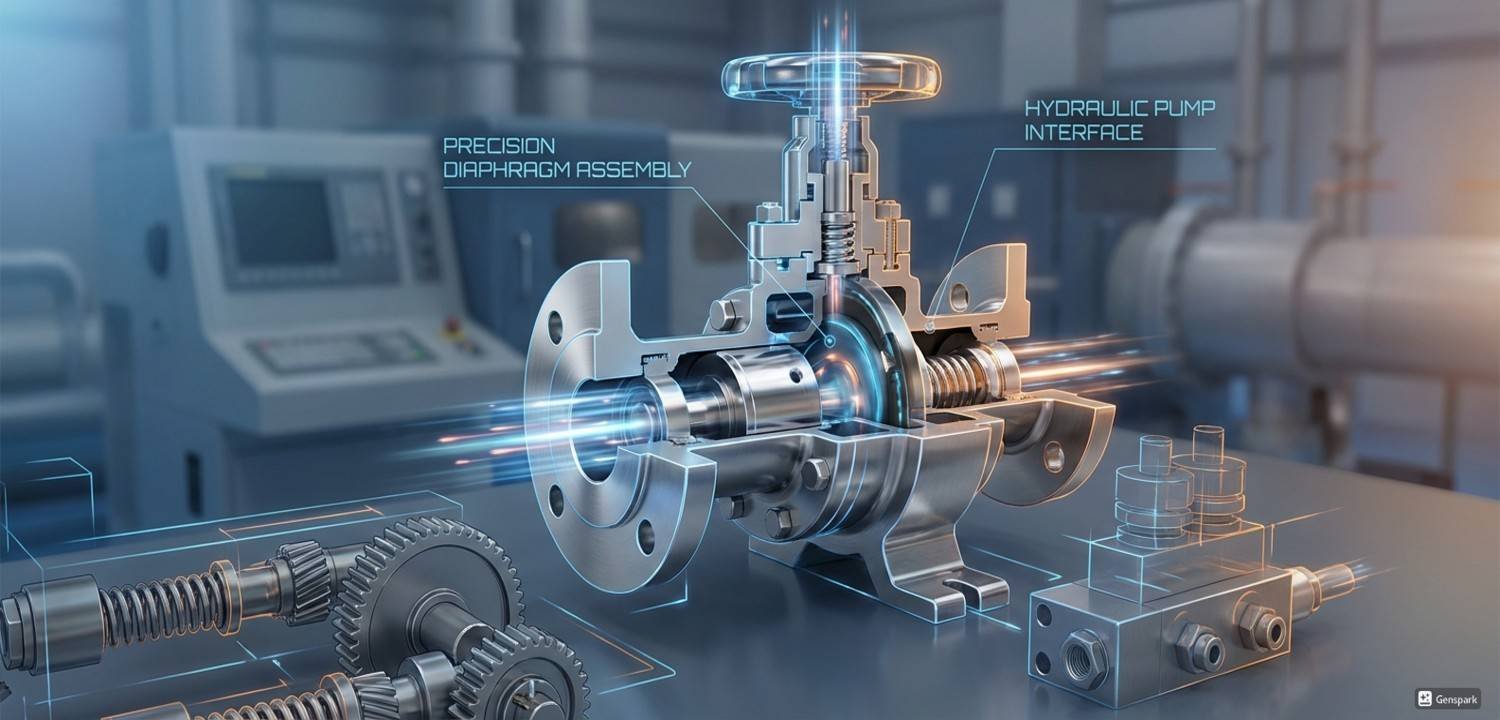

Read MoreWhat Engineers Must Consider When Designing Diaphragms for Valves and Pumps

Posted On 12 February, 2026 By Arvico Rubber Leave a Comment What Engineers...

Read More