What Engineers Must Consider When Designing Diaphragms for Valves and Pumps

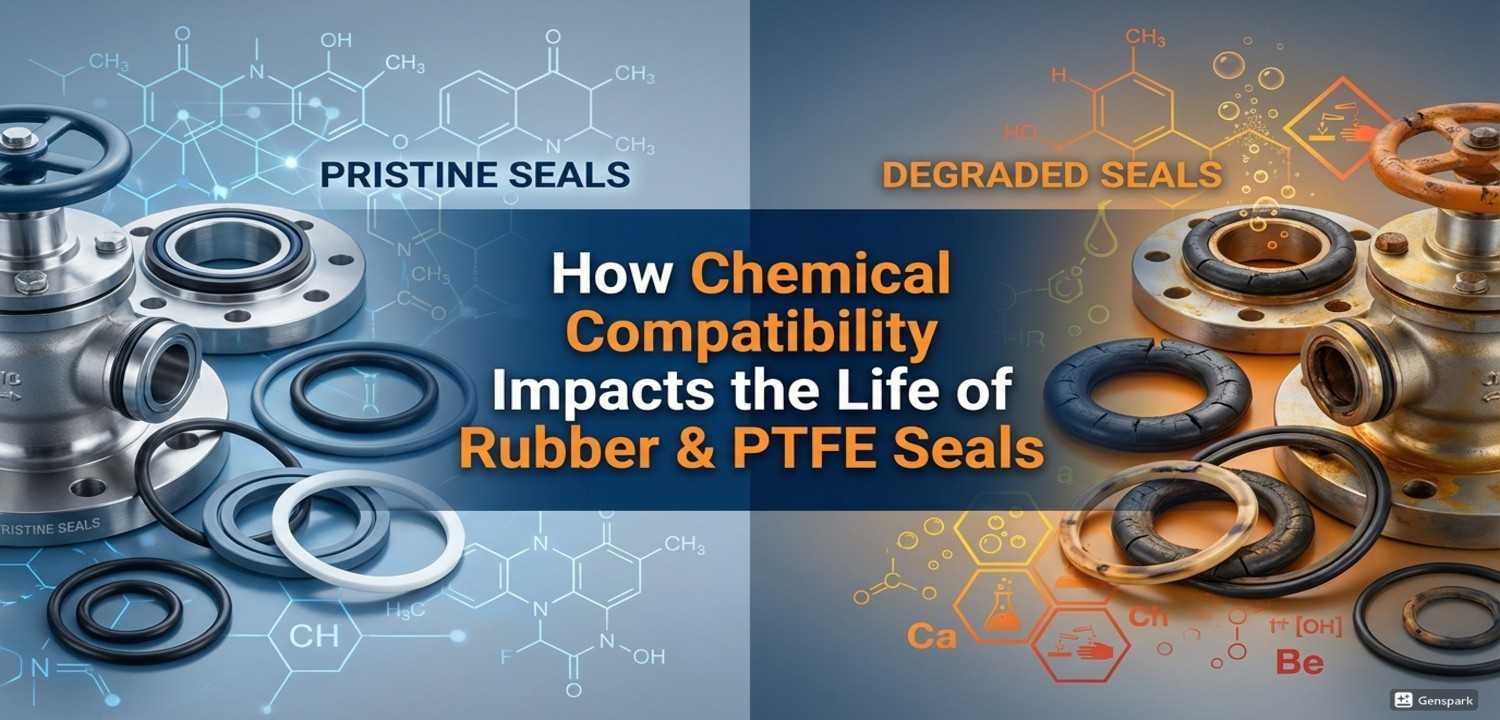

In industrial applications, seals are often exposed to aggressive chemicals, fluctuating temperatures, and continuous mechanical stress. While seal design and installation are critical, chemical compatibility between the sealing material and the operating media is one of the most decisive factors influencing seal life, reliability, and performance. Selecting the wrong elastomer or polymer can lead to early failure, leakage, downtime, and costly maintenance.

Understanding Chemical Compatibility in Sealing Applications

Chemical compatibility refers to a material’s ability to resist degradation when exposed to specific chemicals, such as acids, solvents, oils, fuels, or cleaning agents. When a seal material is incompatible with the media it contacts, it can face physical or chemical changes that may compromise its sealing function.

These changes may not occur immediately but often develop gradually, reducing seal life over time and increasing the risk of unexpected failure.

How Incompatible Chemicals Degrade Rubber Seals

Rubber seals rely on elasticity and resilience to maintain sealing pressure. Exposure to incompatible chemicals can negatively affect these properties in several ways:

- Swelling: Certain chemicals are absorbed into the rubber compound, causing it to expand. Swelling alters seal dimensions and can increase friction or lead to extrusion.

- Hardening or Softening: Chemical reactions may cause rubber to lose elasticity, becoming either brittle or excessively soft.

- Cracking and Surface Degradation: Aggressive media can attack the polymer chains, leading to cracks or surface erosion.

- Loss of ability to return to original shape: Rubber may fail to recover its original shape after compression, resulting in leakage.

For example, standard NBR seals perform well with oils and fuels but degrade rapidly when exposed to strong acids or certain solvents. Similarly, EPDM is excellent for water and steam but incompatible with petroleum based fluids.

PTFE Seals: Superior Chemical Resistance with Design Considerations

PTFE seals are widely used in chemically aggressive environments due to their exceptional chemical inertness. PTFE is resistant to most acids, and corrosive fluids, making it ideal for chemical processing, pharmaceuticals, and food applications.

However, chemical compatibility alone does not guarantee long service life. Engineers must also consider:

- Cold Flow: PTFE can deform under sustained load, especially at higher temperatures.

- Mechanical Support: PTFE seals often require energized designs or backing elements to maintain sealing force.

- Gas Permeation: Although rare, certain gases can permeate over time under high pressure.

Despite these considerations, PTFE remains the material of choice when rubber compounds cannot withstand the chemical environment.

The Combined Impact of Chemicals, Temperature, and Pressure

Chemical compatibility can never be evaluated just on that basis. Temperature, pressure, and dynamic movement can increase chances of chemical attack, which significantly shortens seal life. A material that performs well at room temperature may fail rapidly at higher temperatures in the same chemical environment.

For export oriented OEM applications especially in Europe and the USA, design engineers demand material testing under actual operating conditions, rather than relying solely on compatibility charts.

Why Proper Material Selection Extends Seal Life

Selecting the correct rubber compound or PTFE grade offers several long term benefits:

- Extended service life and reduced maintenance

- Lower risk of leakage and system failure

- Improved equipment reliability

- Compliance with international safety and quality standards

- Reduced total cost of ownership

Working with an experienced seal manufacturer ensures that chemical exposure, operating parameters, and regulatory requirements are fully considered during material selection.

Chemical compatibility plays a critical role in determining the performance and lifespan of rubber and PTFE seals. Incompatible materials can lead to swelling, degradation, leakage, and early failure, often with serious operational consequences. By understanding the interaction between seal materials and operating media, engineers and OEM buyers can make informed decisions that enhance reliability and efficiency.

At Arvico Rubber Industries, we support global customers with custom engineered rubber and PTFE sealing solutions, carefully selected for chemical resistance, mechanical performance, and long term durability across demanding industrial environments.

-

Facebook

-

Linkedin

-

Youtube