Can a very simple and fuss-free product make a significant impact on several industries at the same time? Say hello to the versatile and absolutely vital part of most components and machinery – the O-rings. O-Rings or O-ring seals are loop-shaped elastomers that help seal joints or interfaces.

When two different parts are connected at a joint or an interface, the risk of leaks is high. This is especially true when there is internal pressure in the joint. An O-ring seal fits precisely in the joint grooves and ensures no solid, liquid, gas, or air passes out.

O-rings can be made using different types of rubber and can come in various sizes and shapes. Arvico Rubber has an in-house molding factory where we can custom-design molds and create O-ring seals based on exact customer specifications.

This blog will take you through the basics of O-ring seals, including their uses, properties, and types.

How do O-ring seals work?

O-ring seals are available both in pre-set standard sizes and in custom sizes; all of them work similarly. These rubber, donut-shaped components act like gaskets, creating a more leak-free and safer seal between joints. These seals can be fixed in a groove or in a channel, and they work perfectly well both ways.

Applications of O-ring seals

There are so many applications of O-ring seals in different industries. Some of them include:

- In transmission and fuel systems

- In the functioning of medical equipment and tools like syringes and filters

- In oil refineries and petrochemical industries, to prevent contamination of components

- In the production of electronic equipment to seal the insides from dust and water

- In drinking water production factories, to prevent water contamination

- In chemical industries, to prevent hazardous leakages

- In pneumatic systems, to prevent fluid loss

Static and dynamic applications of O-ring seals

In whichever industry the O-ring seals are used, they are primarily used in two kinds of environments – static and dynamic. As the name suggests, static applications are where the joints or surfaces the O-ring connects don’t move or rub against one another.

In dynamic environments, the O-ring connects two moving parts.

Static O-ring seals can be made of any material of choice, as it doesn’t go through intense wear and tear. However, dynamic O-ring seals definitely need to be made more cautiously. The constant motion will lead to the rubber material going through stress and abrasion, and unless the material is strong and flexible enough, the O-ring will break or get damaged soon.

How are O-ring seals made?

There are so many different techniques used in creating O-ring seals. Some of them include:

- Injection molding – The molten rubber material is injected into a mold and then let to cool down. Different types of elastomers can be molded to create O-ring seals.

- Transfer molding – The process is similar to that of injection molding, but external pressure is applied to push the molten material into the mold. As a result, the final O-ring seal is better created and is precise in shape and size.

- Extrusion – This is a more traditional method where the elastomer is pushed through an opening in the shape of the desired mold using external pressure. As a result, the elastomer takes the shape of the mold and comes out in the desired dimensions.

- Pressure molding – The required mold is divided into two halves here. The elastomer is poured into both these mold halves, and then the molds are joined together using pressure and heat. This helps the elastomer take the required shape.

5 basic features of O-Ring seals

You could be a client looking to create O-ring seals for your production process or a seller looking to resell these components. Either way, you should know these five basic features of O-rings, so you choose the right one for your needs.

1. Diameter

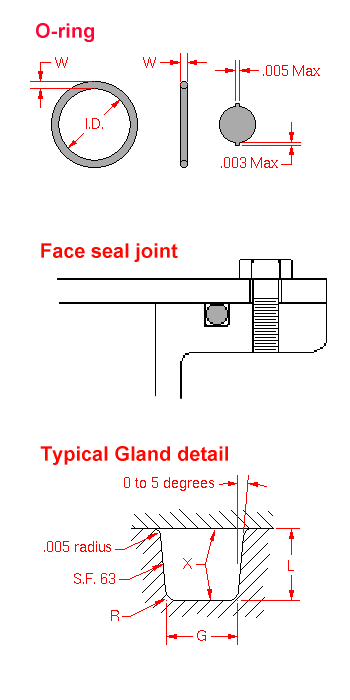

The diameter here includes both internal and external diameters. This is the first basic feature you need to be clear about while talking about O-ring seals. The interior diameter is the length between the inner ends of the O-ring, while the external diameter is the length between the extreme ends. If you are going to buy thousands of pieces of O-rings, then make sure the diameters are measured right, so they fit well.

2. Groove

Groove is used to hold the O-ring seals in place when they are fitted in a joint or inside a machine. The groove design plays a major role in deciding how well the O-ring seals. Talk to your manufacturer and understand different groove designs before picking one.

3. Hardness

Hardness is defined as how strong and durable the material of the O-Ring is. Different types of elastomers have different hardness indexes, and you need to choose the right type to fit your need. For instance, if the O-ring seals will work under extreme pressure/temperature changes, choose materials with a higher hardness index. Levels of more than 90 are usually considered hard.

The below are the hardness indexes of some of the elastomers used by Arvico Rubber.

| Material | Hardness Index |

| Natural Rubber | 30-90 |

| Nitrile Rubber | 20-100 |

| Neoprene Rubber | 30-95 |

| Hypalon Rubber | 40-95 |

| Butyl Rubber | 35-85 |

| EPDM Rubber | 40-90 |

| Silicone Rubber | 25-85 |

| Viton Rubber | 55-95 |

| Polyurethane Rubber | 60-90 |

4. Tensile

Tensile strength is also an important feature of O-ring seals. This talks about the kind of force or pressure that the ring can withstand without breaking. The higher the tensile strength, the stronger the material is.

The below is the tensile strengths of elastomer materials used by Arvico Rubber.

| Material | Tensile Strength (PSI) |

| Natural Rubber | 3000 |

| Nitrile Rubber | 3500 |

| Neoprene Rubber | 3000 |

| Hypalon Rubber | 2500 |

| Butyl Rubber | 2000 |

| EPDM Rubber | 3000 |

| Silicone Rubber | 1100 |

| Viton Rubber | 1800 |

| Polyurethane Rubber | 4000 |

5. Flash

Flash is basically excess material found in the parting line projection resulting from the molding process while creating O-ring seals. Usually, the acceptable levels of flash are the following.

Thickness of flash – 0.13 mm/ 0.005 inches

Extension of flash – 0.08 mm/ 0.003 inches

Different O-ring seal materials

As mentioned above, there are different O-ring seals depending on the material they are made out of. The properties of all these vary, and as a buyer, it is important that you know the types and their features before making a decision.

You should always be able to talk to your manufacturer and get facts right. Arvico Rubber spends the first part of any new project gathering requirements and deciding on the type of O-ring seals the customer may benefit from. We go ahead with the project only after we have a confirmation from the buyer and the buyer is satisfied. Some of the top materials in which you can get O-rings from Arvico are:

- Natural Rubber

- Nitrile Rubber

- Neoprene Rubber

- Hypalon Rubber

- Butyl Rubber

- EPDM Rubber

- Silicone Rubber

- Viton Rubber

- Polyurethane Rubber

Conclusion

O-ring seals are, undoubtedly, one of the most commonly used rubber components across different industries. Whenever there is a need to seal gases, air, liquid, or chemicals, apart from other sealing methods used, the addition of O-ring seals becomes compulsory.

These seals may look like tiny, simple components. However, if they are not of the expected quality, they may lead to leakages, which may cause huge financial losses. At times, such leakages may also turn dangerous to people working in the plant.

That’s why make sure your O-ring seals are made by ISO-certified manufacturers like Arvico Rubber. Our designing and manufacturing teams work hand-in-hand to ensure specifications are thoroughly met and all the products from our warehouse go through multiple stages of testing to ensure they work as expected. Get in touch with us to find out the types of O-ring seals we produce.