Rubber Gaskets

Sealing Precision, Powering Industries – Arvico Rubber Gasket

Rubber gaskets are essential sealing components that create a reliable barrier between two stationary surfaces, preventing leaks, containing fluids, and shielding equipment from contaminants.

By ensuring the integrity of fluid and gas systems, they play a vital role in maintaining seamless operations in piping networks and machinery. Their adaptability across various materials and designs makes them indispensable for industries requiring precision sealing solutions.

At Arvico Rubber, we leverage over 55 years of expertise, cutting-edge technology, and stringent quality control to manufacture high-performance gaskets that deliver exceptional sealing, durability, and resilience in the most demanding environments.

Key Benefits

Built

for Extremes

Withstands high pressure, temperature variations, and harsh chemicals without compromising durability.

Minimal Compression Set

Retains shape and sealing integrity over time for long-term efficiency.

Wear & Impact Resistant

Absorbs shocks, resists UV, ozone, and aging, preventing premature seal failure.

Leak-Proof

Reliability

Precision-engineered tolerances ensure flawless sealing and prevent leaks.

Versatile

& Durable

Designed for demanding industrial environments, ensuring consistent performance in critical applications.

Technical Excellence in Every Gasket

| Property | Details |

|---|---|

| Material Options | Natural, NBR, Neoprene, EPDM, Silicone, FKM, Hypalon, Butyl, FFKM, PTFE – engineered for diverse applications |

| Hardness Range | 30 to 85 Shore A – Customizable for precise requirements |

| Operating Temperature | -60°C to 324°C (Based on Material) |

| Pressure Resistance | Up to 100 Bar (Based on Design) |

| Colors | Available in standard and custom colors |

| Processing Services | Moulding, Die-Cutting, Flash Cutting, CNC Fabrication |

| Size Range | Customizable in size from 2 mm to 2000 mm, from micro washers to large industrial gaskets. |

Where Our Gaskets Work

- Oil & Gas– High-performance sealing for pipelines, compressors, and containment systems.

- Chemical Processing– Resistant to withstand harsh chemicals, ensuring safe and reliable operations.

- Water Treatment– Corrosion-resistant gaskets for valves, pumps, and treatment units.

- HVAC & Insulation– Reliable duct sealing, vibration dampening, and thermal insulation solutions.

- Food & Beverage– Hygienic, FDA-compliant gaskets for safe processing and packaging.

- Automotive & Aerospace– Precision sealing for engines, transmissions, and fuel systems.

The Right Gasket for Every Challenge

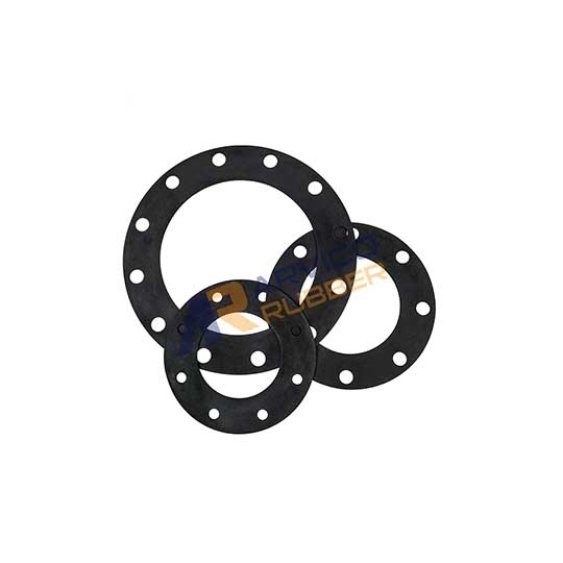

- Flange Gaskets:For secure pipe and equipment connections in oil & gas, water, and chemical industries.

- Die-Cut Gaskets:Custom-fabricated for precision sealing in automotive, aerospace, and machinery.

- Tri-Clover (TC) Gaskets:Hygienic, high-purity seals for biotech, pharmaceutical, and food processing industries.

- Sponge/Foam Gaskets:Cushioning, sound absorption, and sealing for enclosures and HVAC systems.

- Flat Gaskets: Versatile sealing solutions for smooth, even surfaces in industrial applications.

Flange Gasket

Diecut Gasket

Butterfly Valve Gasket

TC Gasket

Washers

Gasket

Sealing the Future – Why Choose Arvico?

- 55+ Years of Expertise – A legacy of engineering excellence and innovation.

- Precision Manufacturing – Cutting-Edge Crafted with ±0.01 mm accuracy for reliable performance.

- Scalable Production – Meeting bulk and custom OEM requirements efficiently.

- Certified Quality – CE, ISO, GMP, REACH, ROHS-approved for global compliance.

- Advanced Customization – Tailored solutions for industry-specific sealing needs.

Let’s Seal Success Together!

Looking for high-performance rubber gaskets built to last? Partner with Arvico for sealing solutions that redefine reliability and efficiency.