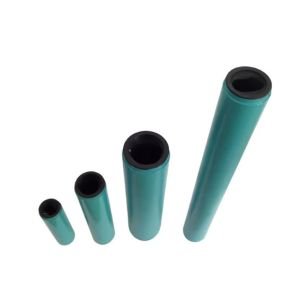

Rubber Stators

Engineered Rubber Stators for Demanding Pumping Systems

Rubber stators are the static counterparts in rotary pump systems that interact directly with rotors to enable seamless fluid movement. The quality and resilience of this interaction determine the operational integrity of your entire pumping system. At Arvico Rubber, we design and manufacture high-performance rubber stators engineered for seamless fluid transfer in progressive cavity and screw pumps. With superior resistance to abrasion, chemicals, and temperature extremes, our stators are built to thrive in high-demand environments – from oilfields to food plants. Each unit is crafted with precision, using premium elastomers and proven engineering practices to ensure maximum sealing efficiency and longevity.

What Sets Our Stators Apart

Engineered to

Endure

Withstand abrasive media, temperature variations, and continuous operational stress without degradation.

Custom-Fit

Designs

Tailored profiles, geometries, and compounds to match your specific pump configuration and duty cycle.

Superior Material

Integrity

Made with high-grade elastomers offering excellent mechanical and chemical resistance.

Casting

Flexibility

Available with or without metallic outer casings to suit your mounting or application preferences.

Efficiency-Driven

Sealing

Optimized internal contours for smooth rotor engagement and consistent volumetric output.

Performance Parameters

| Property | Specification |

|---|---|

| Material Options | Natural, Nitrile (NBR), EPDM, Silicone, Viton, Neoprene, Hypalon, Butyl |

| Size Range | Customized diameters and lengths |

| Hardness | 65 – 85 Shore A |

| Temperature Range | -50°C to +200°C (based on material) |

| Color Options | Standard & custom colors |

Stators

Stators

Versatile Applications, Reliable Results

- Oil & Gas – Reliable pumping of viscous fluids, drilling slurries, and hydrocarbons.

- Chemical & Process – Designed to handle corrosive and reactive chemical compounds.

- Wastewater & Effluent – Maintains performance in challenging flow and pressure conditions handling sludge and chemical dosing.

- Mining & Construction – Pumping grout, mortar, and abrasive mixtures.

- Food & Beverage – Food-safe Hygienic stators available for regulated environments and product handling like sauces, pastes, and dairy.

- Pharmaceuticals – Cleanroom-grade stators for sterile and sensitive product movement.

Why Arvico? Because Precision Matters.

With over five decades of rubber engineering expertise, Arvico specializes in crafting high-performance stators for progressive cavity and screw pumps. From elastomer formulation to geometry design, every stator is customized to meet the exact mechanical and chemical demands of your system. Whether it’s FDA-compliant materials for hygienic processing or rugged compounds for abrasive media, our flexible manufacturing supports both niche applications and high-volume OEM needs. What truly sets Arvico apart is not just the quality of our stators—but the precision, consistency, and speed with which we deliver them. Backed by in-house compounding, real-world testing, and stringent quality control, we ensure your pumps keep running smoothly—every single day.

Let’s Build the Right Stator for You

Looking for the perfect rubber stator for your pump system? Our team is here to help you find or create a solution that matches your exact requirements.

Let Arvico help you power your pump performance.