Problem Statement

The client had ordered stators from a local vendor which had longevity issues. The procured stators stopped working within 15-20 days.

The client required good quality stators with long shelf life.

Challenges

The requirement had to be fulfilled during the Covid pandemic.

Solution

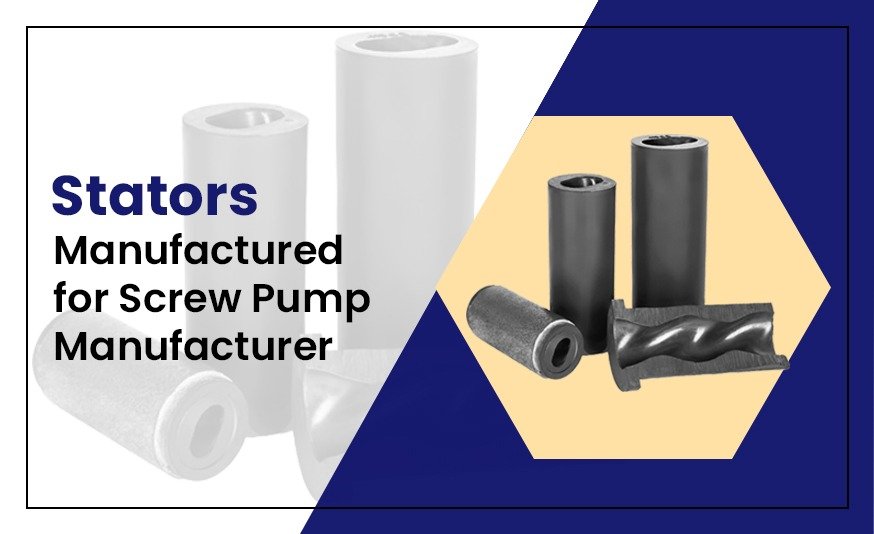

The below steps were followed to manufacture stators that were designed to be durable with longer life. The design and manufacturing included the below:

- Used High Nitrile rubber which is suitable for adhesive applications

- The rubber was molded at 160 degrees for better vulcanization

- Hardness of 70/75 was maintained for the application

Results Achieved

After installing the rubber stators, the components performed for a longer time, could sustain the pressure and temperature. The order processed included 30 stators.

The client was happy with the delivery and the products supplied were approved without any rework required.