What Engineers Must Consider When Designing Diaphragms for Valves and Pumps

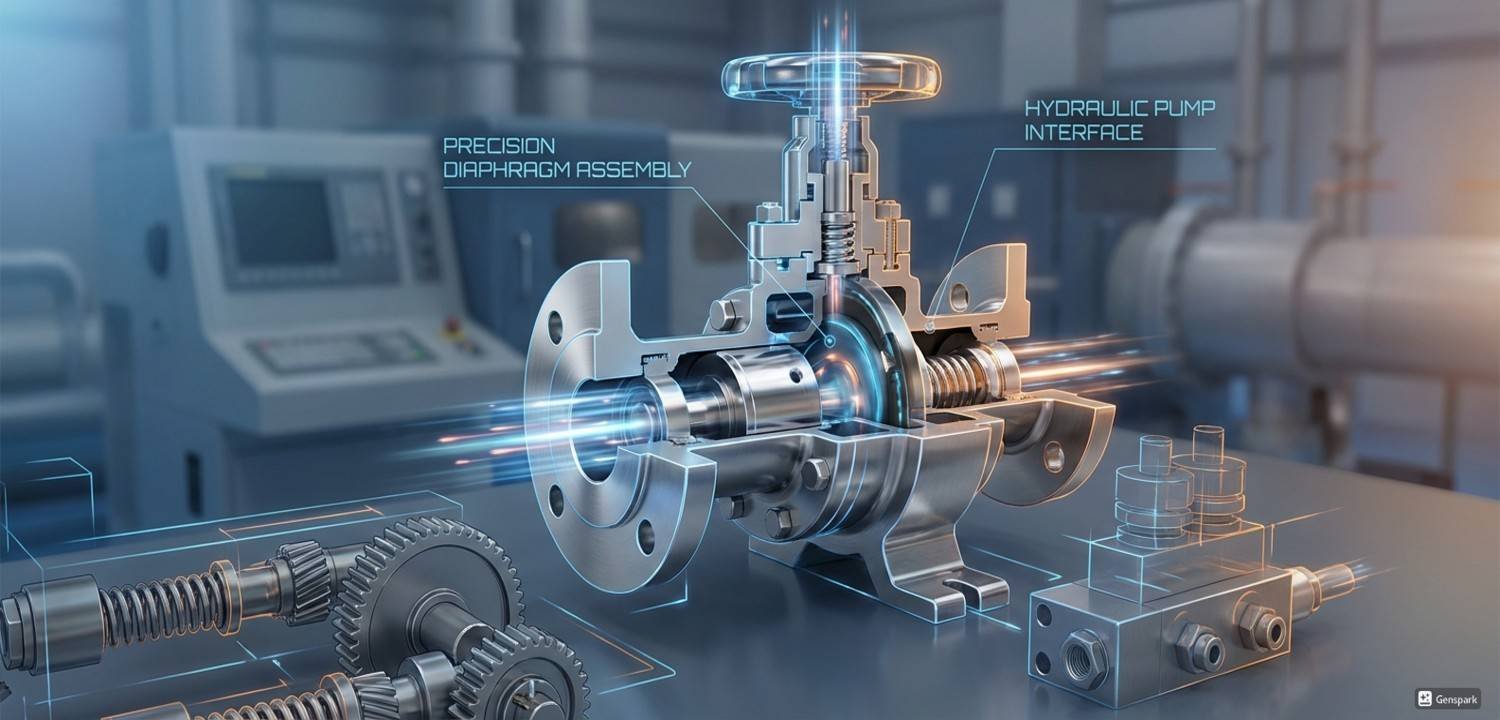

Diaphragms are critical components in valves and pumps, they are pretty much the heart of a machine. It directly influences sealing performance, flow control, and equipment reliability. Inferior diaphragm design can result in reduced efficiency, leakage, frequent maintenance, and early failure. For engineers designing diaphragms for industrial valves and pumps, careful consideration of operating conditions, material properties, and mechanical performance is essential.

Following are the factors which engineers must consider.

1. Operating Pressure and Pressure Cycling

One of the first considerations in diaphragm design is the operating pressure range, including pressure fluctuations. Diaphragms in pumps and valves often experience repeated pressure cycling, which can cause fatigue over time. The diaphragm must be designed to withstand both peak pressure and continuous dynamic loading without cracking or permanent deformation.

2. Temperature Range

Temperature has a direct impact on diaphragm performance. High temperatures can reduce elasticity, while low temperatures may cause stiffness or brittleness. Engineers must account for both operating and ambient temperatures when selecting diaphragm materials and thickness to ensure consistent performance throughout the service life.

3. Chemical Compatibility with Process Media

The diaphragm is in constant contact with any substance passing by. Exposure to harsh chemicals, oils, solvents, or gases can degrade unsuitable materials. Selecting chemically compatible materials such as PTFE, elastomers, or composite diaphragms is essential to prevent swelling, hardening, or loss of sealing strength.

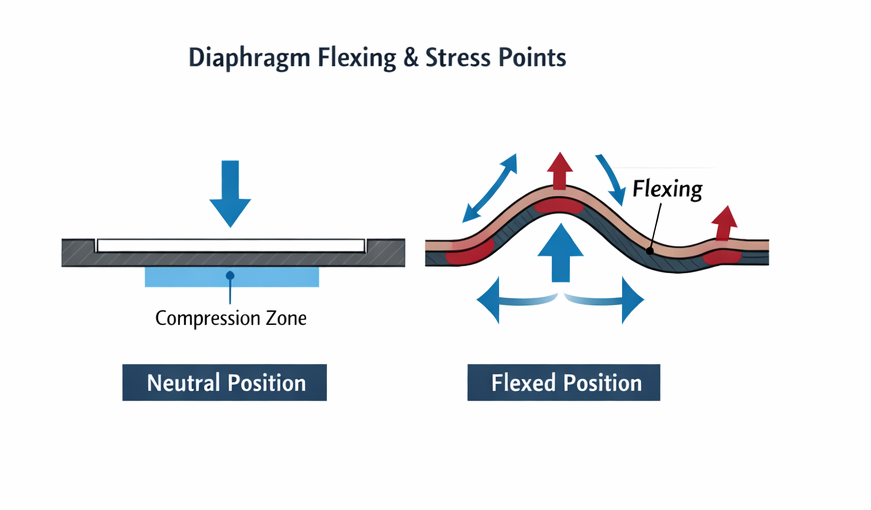

4. Flex Life and Fatigue Resistance

Diaphragms operate under continuous flexing, making resistance a critical design parameter. The diaphragm dimensions, reinforcement, and material composition must support high cycle life. Optimized diaphragm profiles reduce stress concentration and extend service intervals in pumps and valves.

5. Diaphragm Geometry and Design Profile

The shape, thickness, and design of a diaphragm significantly influences its movement and sealing efficiency. Engineers must design diaphragms that allow uniform deflection while maintaining right sealing force. Poor design can lead to uneven stress distribution and early failure.

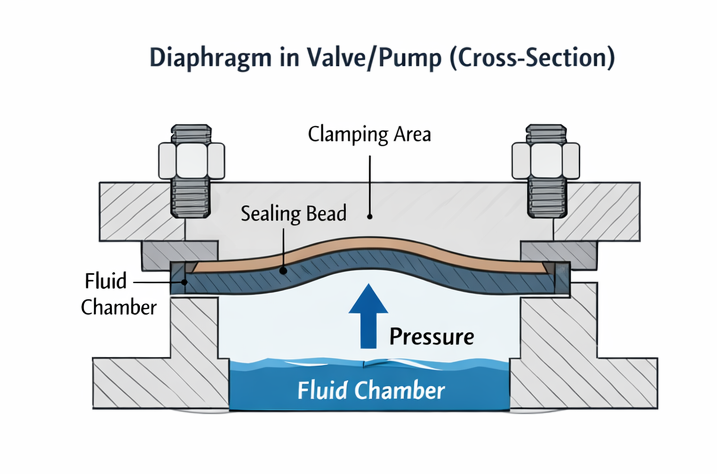

6. Sealing Interface and Clamping Design

The sealing bead, clamping area, and interface between the diaphragm play a crucial role in leak prevention. Proper sealing design ensures the diaphragm remains securely positioned during operation, even under vibration or pressure variation. Accurate tooling and tolerance are essential for consistent sealing performance.

7. Material Hardness and Elastic Recovery

Material hardness affects how well a diaphragm seals and recovers after compression. A balance between flexibility and strength is required to maintain sealing pressure over time. Engineers must select appropriate hardness levels to avoid excessive wear or loss of elasticity during prolonged use.

8. Manufacturing Method and Quality Control

The methods of diaphragm’s manufacturing process are compression moulding, transfer moulding, or PTFE forming which directly impacts dimensional accuracy and performance consistency. Diaphragm manufacturers implement strict quality control measures, including dimensional inspection and functional testing, to ensure results across production.

9. Compliance with Industry Standards and Application Requirements

Depending on the application, diaphragms may need to meet specific industry or regulatory standards. Engineers must consider compliance requirements related to safety, performance, or environmental regulations, especially for applications in chemical processing, water treatment, pharmaceuticals, and oil & gas industries.

Designing diaphragms for valves and pumps requires a detailed understanding of operating conditions, material behavior, and mechanical performance. By considering factors such as pressure, temperature, chemical compatibility, life, and sealing design, engineers can ensure

-

Facebook

-

Linkedin

-

Youtube